Grip Strut Safety Grating

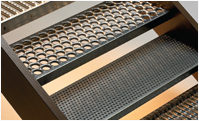

Grate Lock Grating

GRATE-LOCK™ grating is an easy-to-install system of interlocking grating planks, treads, and accessories that provides safe, sturdy footing for mezzanine floors, platforms, walkways and other applications where non-slip performance is required. Hundreds of sole-gripping dimples insure a safe surface in all kinds of weather and environments. The grating is available textured for safer working surfaces and non-textured for wheeled traffic or rack decking.

Grip Strut Plank Grating

Tested by an independent laboratory for slip resistance according to standards and methods established by Federal Specifications RR-G-1602A, Grip Strut® Safety Grating proved its superiority by exceeding all requirements of this specification.

The standards where exacting - five shoe sole materials tested in three directions under five conditions: dry, greasy, muddy,

soapy and icy. Grip Strut Safety Grating tested 10% to 180% more slip-resistant than similar materials, depending on shoe materials and surface conditions.

In survey after survey, accidents caused by falls are high on the list of disabling and lost-time injuries and death. In fact,

statistics from many states rate this type of accident second as the cause for industry’s loss of manhours and lower productivity. As proved in the test described above, Grip Strut Safety Grating substantially reduces this kind of accident. In

addition, the hazard of falling objects is minimized by the shape and size (17/8” x 11/16”) of the surface openings. Fewer accidents, with resultant lower insurance costs and reduced workman’s compensation losses, should be the logical reason for specifying Grip Strut Safety Grating for all walking-working surfaces and stair treads.

Perf-O-Grip Grating & Traction Tread Flooring

Every year industrial accidents — falling, tripping over debris, slipping on wet or greasy surfaces — cost millions of dollars in lost man-hours and production. Insurance costs often are reduced when accident rates decline. Perf-O-Grip Grating and Traction Tread Flooring help cut accident rates by providing safer walking-working surfaces.

Perf-O-Grip Grating’s unique surface of large debossed holes and perforated buttons provides maximum slip protection and performance under practically all conditions and in every direction.

The large debossed holes allow fluids, mud, chips and other accident-causing debris to drain away. With 5 inch high side channels, Perf-O-Grip Walkways meet OSHA requirements for toeboards on elevated structures. Canadian OH & S compliant designs are also available.

In addition to providing safety, the resilient surface of Perf-OGrip Grating cushions the impact of footfalls thereby lessening worker fatigue and increasing efficiency. Perf-O-Grip Grating is your best safety buy. It cuts costs and helps improve plant productivity.

Heavy-Duty Grip Strut Grating Walkways & Planks

Heavy-Duty Grip Strut Grating Walkways and Planks are available in three thicknesses of steel, one of aluminum: walkways have one standard siderail height, planks have four. In each category, walkways come in three widths, planks in five. Begin sizing, for maximum economy, with widest practical grating for the job (shallowest siderails and thinnest gauge); if this does not meet required load capacity, first consider deeper siderails, then heavier gauge, and finally narrower grating width, if necessary.

Flexural load tables have been calculated according to design load limiting criteria, and if not illustrated in this catalog they can be obtained from Cooper B-Line technical services.

“Strut Load Tables” show flexural strength and deflection of individual grating surface struts relative to siderails. Since these are maximum values in the elastic range, lesser

loads/deflections can be proportioned from them.